ENGINEERING & MANUFACTURING

MANUFACTURING & ASSEMBLY

Phantom Global provides engineering solutions for the manufacture and assembly of all your components and special-purpose machinery by providing services in the following areas:

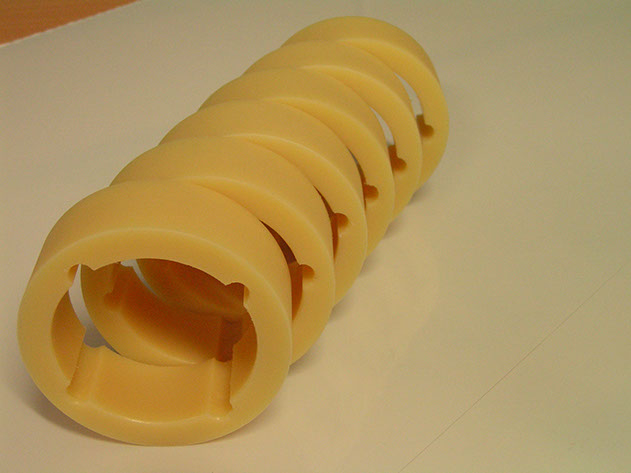

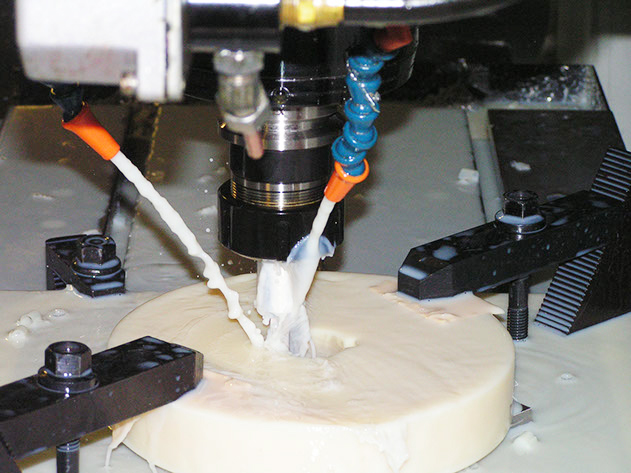

- Precision CNC machining for metals and plastics

- 3D & 4 axis high-speed Milling

- CNC Turning\ Bar Feed\ Parts Catcher

- CNC Micro Turning high speed with C Axis live tooling

PROJECT MANAGEMENT

From concept to delivery, Phantom Global can manage all or part of the design and manufacturing process for customers.

By combining the staff with problem-solving and specialist skills, a project can be managed from start to finish, managing any risk factors and working within customer specifications and budgetary requirements.

Phantom Global can offer a complete solution for your manufacturing requirements. This may include the design of new parts to problem-solving on existing components and verifying or correcting problems prior to manufacture saving time and reducing the expense of costly mistakes.

The advantage of in-house CAD design capability that allows us to design in a range of formats, which can be emailed to customers. Customers without CAD or drawing experience can open files and easily visualize in window-based viewers the concept design, thus saving time from design to prototype or production.

At Phantom Global, we can provide you with:

- CNC Milling

- CNC Turning – C Axis – Bar Feed – Parts Catcher

- Stainless Steel & Mild Steel Fabrication

Quick CNC quotes

Email your 3D CAD data, define your project specs and a quote will be sent back to you in 24 hours or less.

Fast Time – to – Market

Rapid prototype lead time for CNC machined parts is 5 – 7 days depending on geometry.

3D Printing

If requested we can print a 3D model of your product before we start the machining process to better understand that what you have designed will work in once machined. Email your .stl file to us and we can print the model in 48 hours depending on geometry.

COMPETITIVE SKILLS

With a unique combination of manufacturing, design and products development, Phantom Global can provide a broad mix of solutions for industry. We work with customers to provide tailor-made solutions to meet their specific needs and timeframe restraints. The company has 550 sqm of workshop floor space and 100 sqm of office space. Phantom Global has modern CNC equipment which is maintained, calibrated and serviced to the highest standards to ensure quality can never be compromised.

About Us

Phantom Precision Engineering is a precision CNC machine workshop located in Adelaide, South Australia. We are dedicated to providing on-time service for rapid prototyping or small batch run machining projects. Expertise in machining all material types (including plastics) on our Haas machining centres and lathe, give us an advantage over general large batch run workshops. We specialise in providing advice to design engineers when wanting to machine complex, unusual material type parts. Jobs in the past included aluminium, stainless steel, brass, beryllium copper, titanium, acetal, nylon, etc.